Company

The company Alpin Kom was established in 2004. Just from the beginning the company specialized itself in producing high quality molded plywood parts for chairs, like seats, backrests, shells, armrests and legs. The company has its own beech veneer production line so the quality of the plywood is guaranteed. The whole factory has around 10 000 m2 covered working space with over 300 employees. The capacity of the company is more than 100000 pieces of molded plywood parts (seats, backrests, shells, armrests, legs) per month.

Our company is completely environmentally friendly oriented, as we are using raw material purchased from sustainably managed forests and FSC® certified suppliers. For the production of plywood we use adhesive, which complies with the E1, TSCA and F**** formaldehyde emission standards. We are also holders of the CARB certificate. Being able to produce high quality plywood parts while keeping competitive prices is the number one reason why customers choose us. We provide first-class service and industry leading lead time. That is why our company is a proud partner of many valuable furniture brands worldwide like STOKKE, Ikea etc.

Alpin Kom is the main chairs and plywood chair components supplier of almost all national chair manufacturers and resellers, and with its around 90% export orientation is one of the biggest plywood chair components supplier in the Balkans, Western Europe and Scandinavia.

Established in 2004

10000 m2 covered working space

300 employees

100 000 pieces capacity per month

90% Export oriented

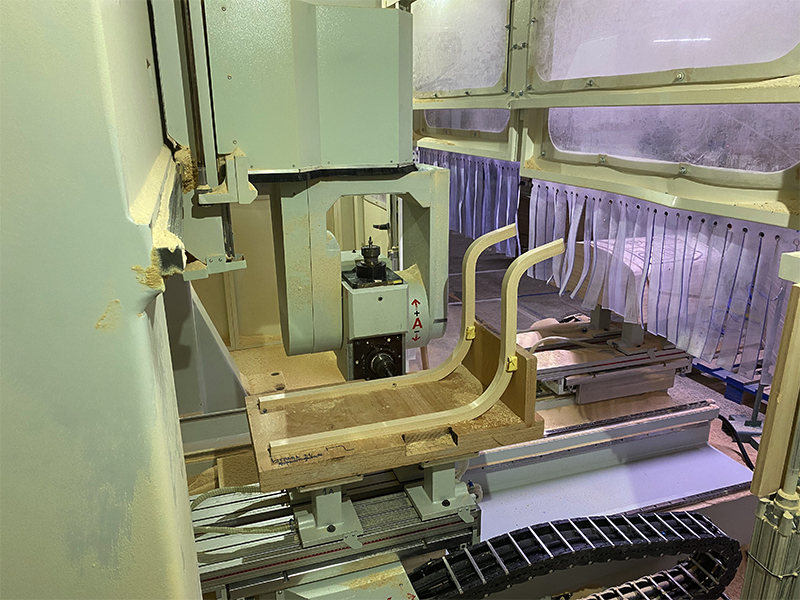

Production & Technology

Products

Contact us

Head office

e-mail: info@alpinkom.mk

Ljupco Lazarevski

CEO

MOB: +389 (0)70 954 740

e-mail: l.lazarevski@alpinkom.mk

Bosko Lazarov

COO

MOB: +389 (0)71 246 520

e-mail: b.lazarov@alpinkom.mk

Company adress

str.Vera Jocik n.8 ; 2320 Delchevo, NMK

Factory location

Atar na s.Grad (Gradski preod), Delchevo, NMK